Intelligent agricultural autopilot system

The principle of beidou automatic navigation and driving system

Beidou automatic driving system is a concentration of satellite navigation, positioning and control in an integrated system, mainly by the GNSS antenna, industrial computer, Angle sensors, ECU controller, steering motor and other parts, according to the position sensor (GNSS satellite navigation system, etc.) to design a good walking paths, and the rotation of the wheels of the coordinates of the satellite positioning, real-time controller sends a command to the steering motor by controlling the steering motor and control the motion of the vehicle, make sure the vehicle according to the route of navigation display. And the precision of the operation is controlled within ±2.5 cm for agricultural cultivation, which can be used for target land, rotary tillage, longlong raising, sowing, spraying, harvesting and other agricultural

The system can be divided into base station part and vehicle-mounted part from the place where the equipment is placed.

1. Base station:

Receiver: receiving beidou /GNSS satellite signals, and real-time output of high-precision RTK difference data;

Antenna: receive beidou /GNSS satellite signals;

Transmitting station: high-power transmitting station, used for differential data transmission of base station;

Radio transmitting antenna: used for transmitting radio signals;

2. Vehicle parts:

High-precision tablet computer: receive satellite signals, combine with differential radio data, output accurate positioning information; Intuitive user interface, easy to adjust the operation mode and control the automatic driving state;

Angle sensor: real-time sense of vehicle steering Angle and send high-precision steering information to the controller;

Controller: according to the beidou receiver and Angle sensor information, calculate and process the information received from the beidou receiver and Angle sensor, and send real-time instructions to the steering motor;

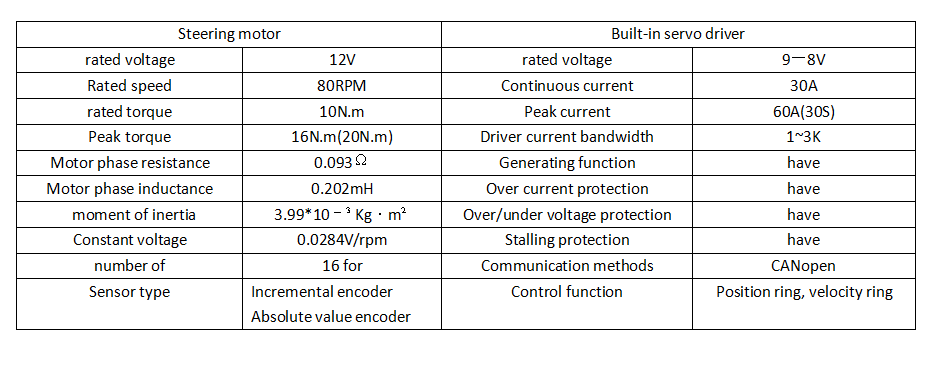

Steering motor: low speed, high torque, high precision, fast response, built-in driver, CAN bus communication, receive controller instructions, control the direction of vehicle driving.

2.1 system advantages

1, greatly improve the operating standards of agricultural machinery, the operation line and line of the kilometer error within 2.5 centimeters.

2, in order to ensure a high standard of operation quality, extend the operation time of agricultural machinery, can achieve a high standard of 24 hours of operation.

3, can effectively improve the utilization rate of land. Practice proves, can raise land utilization rate 5% ~ 10%. Can effectively improve the utilization rate of sunlight and water in the land, so that each plant evenly distributed, enjoy the same space of sunlight and water. Reduce the proportion of weak plants.

4, the automatic navigation and driving system can greatly reduce the labor intensity of the driver, free the driver's hands and eyes, more energy and time to pay attention to the operation of agricultural machinery and farm tools, better ensure the normal operation of agricultural machinery and tools.

5. After supporting the mobile base station, it is not restricted by the region, and the operation of the locomotive can make the driver easily realize the high standard operation.

I. application significance

The development of steering wheel direct drive servo motor of agricultural machinery is mainly benchmarked precision agricultural machinery and driverless steering wheel drive. Makes the agricultural machinery operation implementation of accurate location, can improve the agricultural productivity, high efficiency utilization of agricultural resources, protect the ecological environment, is to achieve high quality, high yield, low consumption, environmental protection is an effective means of the sustainable development of agriculture, can realize fast on the large area of cultivated land, high efficiency, high precision, automation, available to the soil preparation, planting, harvesting, pesticide spraying, and other production, greatly improved production efficiency and land utilization.

Ii. Performance features:

Torque inertia is smaller than that of high coupling stiffness, high response speed, fast position resolution, high linearity and high torque fluctuation coefficientLow speed high torque small hollow shaft interface installation

3. Application field:

4. Parameter table: